Inspections of the support systems

“Reliable inspection and documentation – directly in your system.”

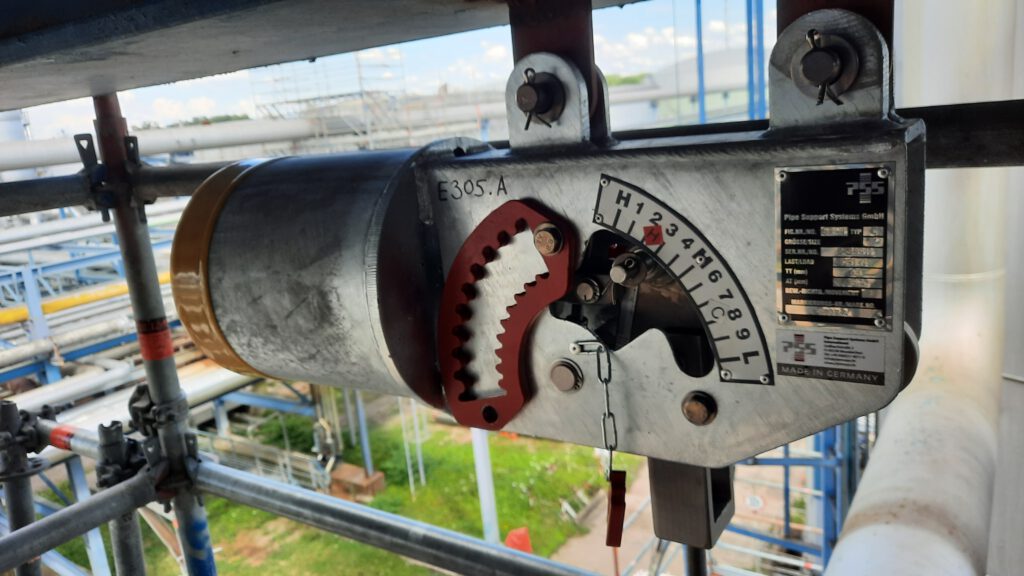

Our inspections of mounting systems include a thorough visual inspection of snubbers, constant and variable spring hangers and other critical components. We carry out these inspections directly on site in your plant and document the condition and functionality of each component in detail. This gives you a complete overview of the condition of your mounting systems and allows you to plan preventive maintenance measures in a targeted manner.

Our inspection service comprises:

- Recommendations for maintenance work: Suggestions for preventive maintenance or necessary repairs to increase operational safety.

- Visual inspection: Checking shock absorbers, snubbers, constant and variable spring hangers for functionality and wear.

- Documentation of the results: Create detailed reports on the condition of each tested component.

Installation and dismantling work

“Efficient installation and removal of mounting systems and accessories – directly on site.”

Our assembly and disassembly service enables you to have snubbers, constant and variable spring hangers, sway struts, pipe guides and other accessories professionally installed or removed from your system. All work is carried out by our experienced team, who place particular emphasis on safety and precision to ensure that assembly and disassembly is carried out quickly, efficiently and without disrupting ongoing operations.

Our installation and dismantling service comprises:

- Preparation of detailed documentation: Seamless recording of the work carried out with detailed reports and supporting images for tracking and quality assurance.

- Assembly and disassembly of individual products: Professional installation and removal of shock absorbers, snubbers, constant and variable spring hangers, sway struts, pipe guides and accessories.