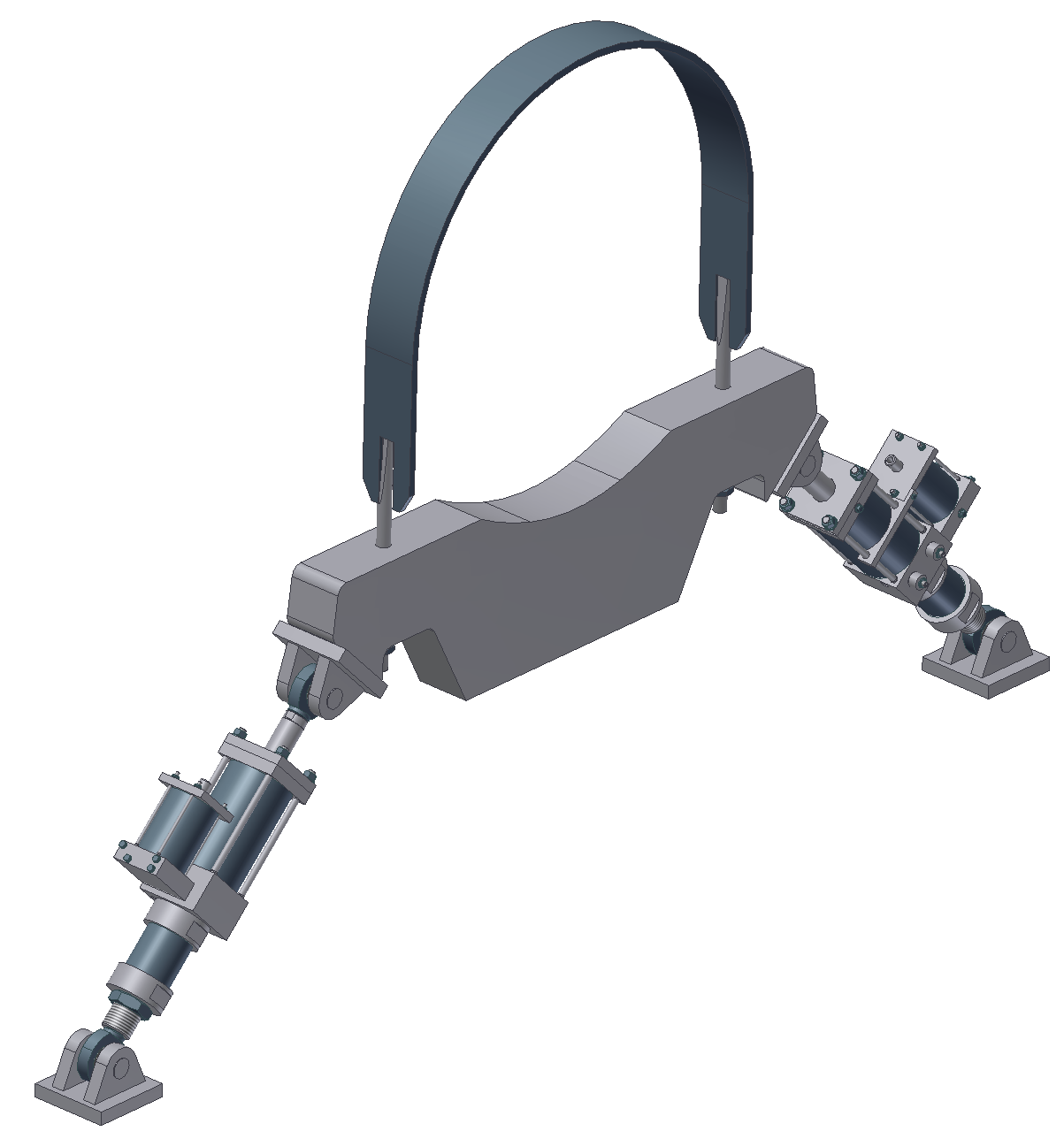

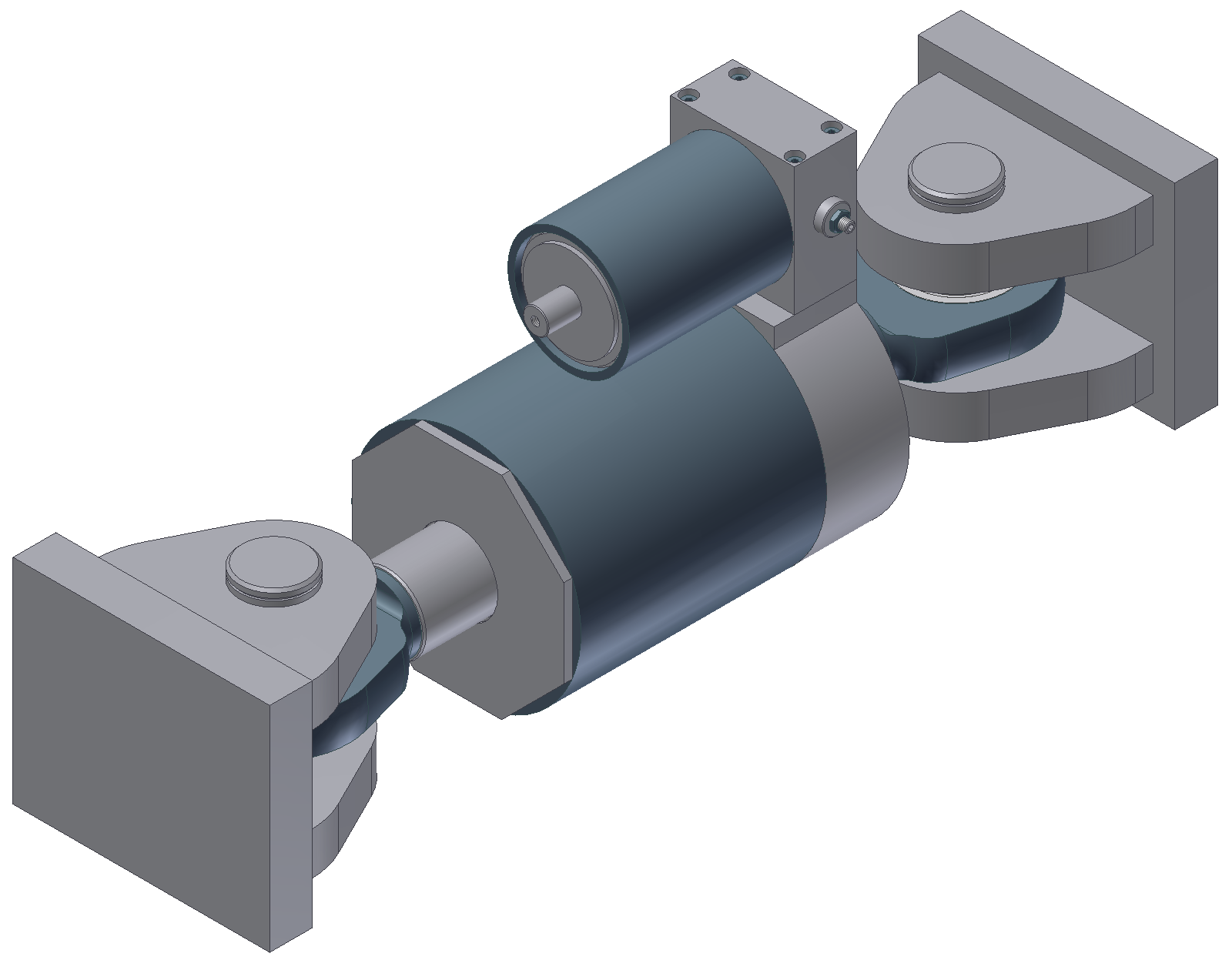

Application

Hydraulic shock absorbers and snubbers are safety-relevant components that are used to protect pipelines and system components. The hydraulic shock absorbers and snubbers specially developed by PSS prevent damage to equipment, pipelines, pressure vessels, valves and pumps that could be caused by sudden dynamic forces. Such stresses are often caused by operational events such as water hammers, pipe bursts or pressure surges, for example when safety valves are blown off. External influences such as earthquakes, explosions or wind loads can also cause considerable dynamic loads, which a hydraulic shock absorbers and snubber reliably absorbs.

In addition, the hydraulic shock absorbers and snubbers can be used as vibration dampers for vibrating pipelines and system components. They are designed to keep dynamic displacement amplitudes to a minimum in order to ensure the stability of the system. However, they do not impair the movement resulting from thermal expansion, so that temperature-related changes can take place unhindered.

Function

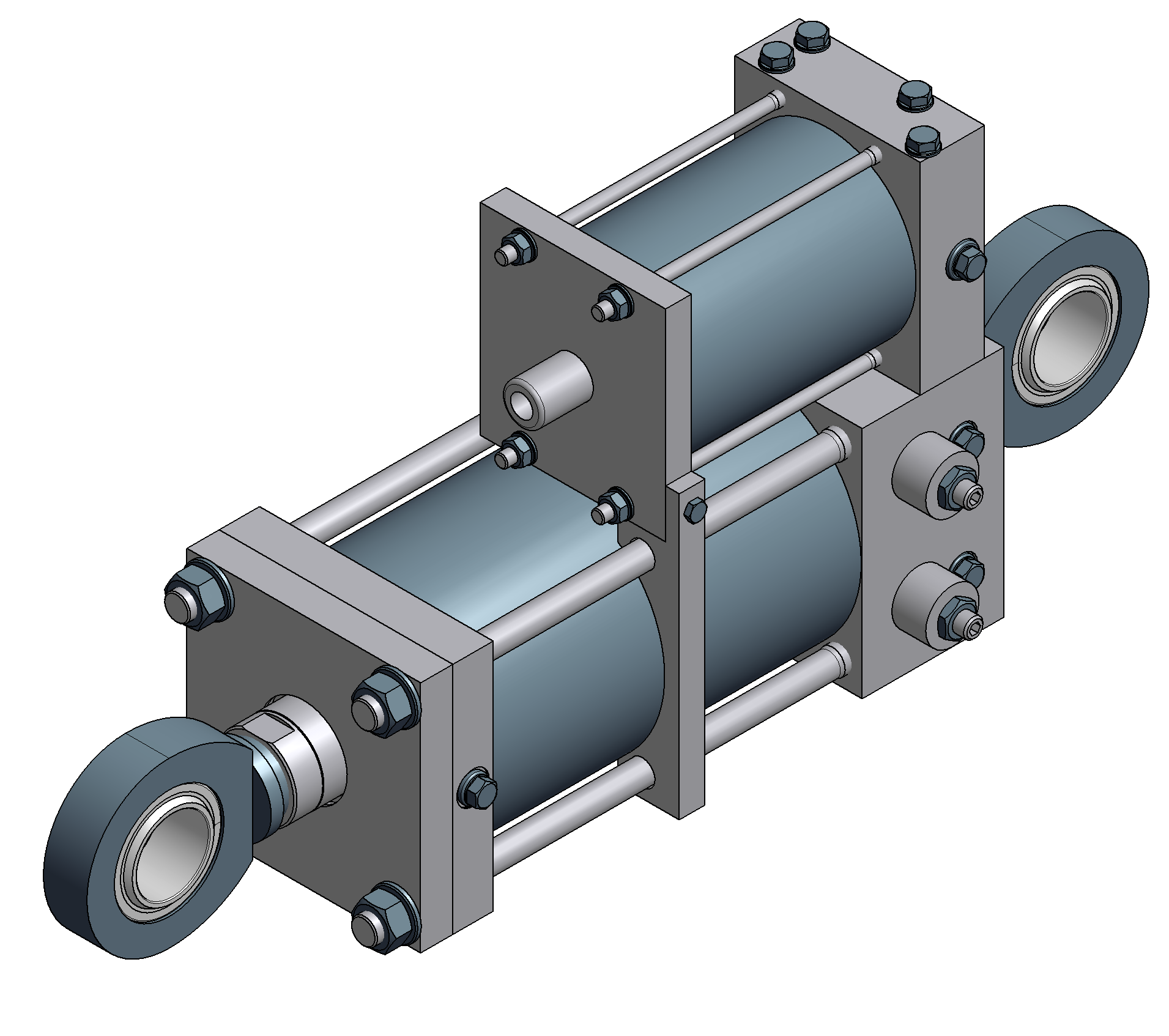

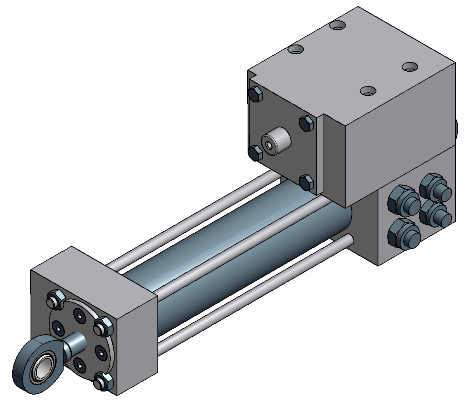

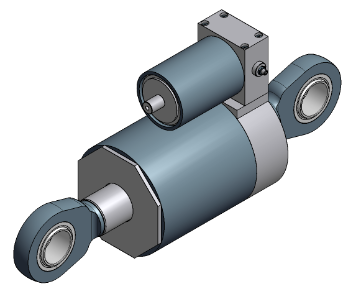

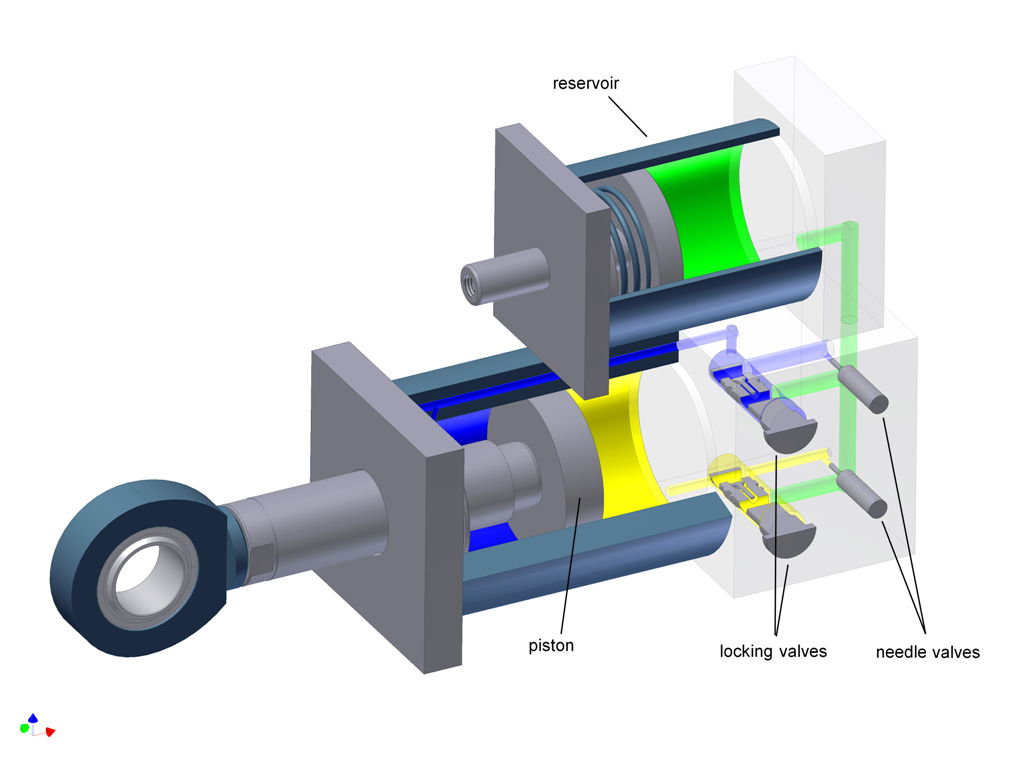

The hydraulic shock absorber / snubber from PSS reacts specifically to dynamic loads. If the piston is moved faster than the set locking speed, the non-return valve closes, inhibiting the flow of silicone oil. At this moment, the snubber absorbs forces and protects the system from damaging movements.

If the direction of movement is reversed or the load decreases, the non-return valve opens and the piston can move freely. During oscillating movements, the non-return valve opens and closes alternately so that the brake absorbs forces in both the tension and compression directions.

The integrated overflow valve or needle valve plays an important role by allowing the piston to yield in a controlled manner up to the specified nominal load. In this way, the system ensures stability without compromising flexibility for thermal expansion.

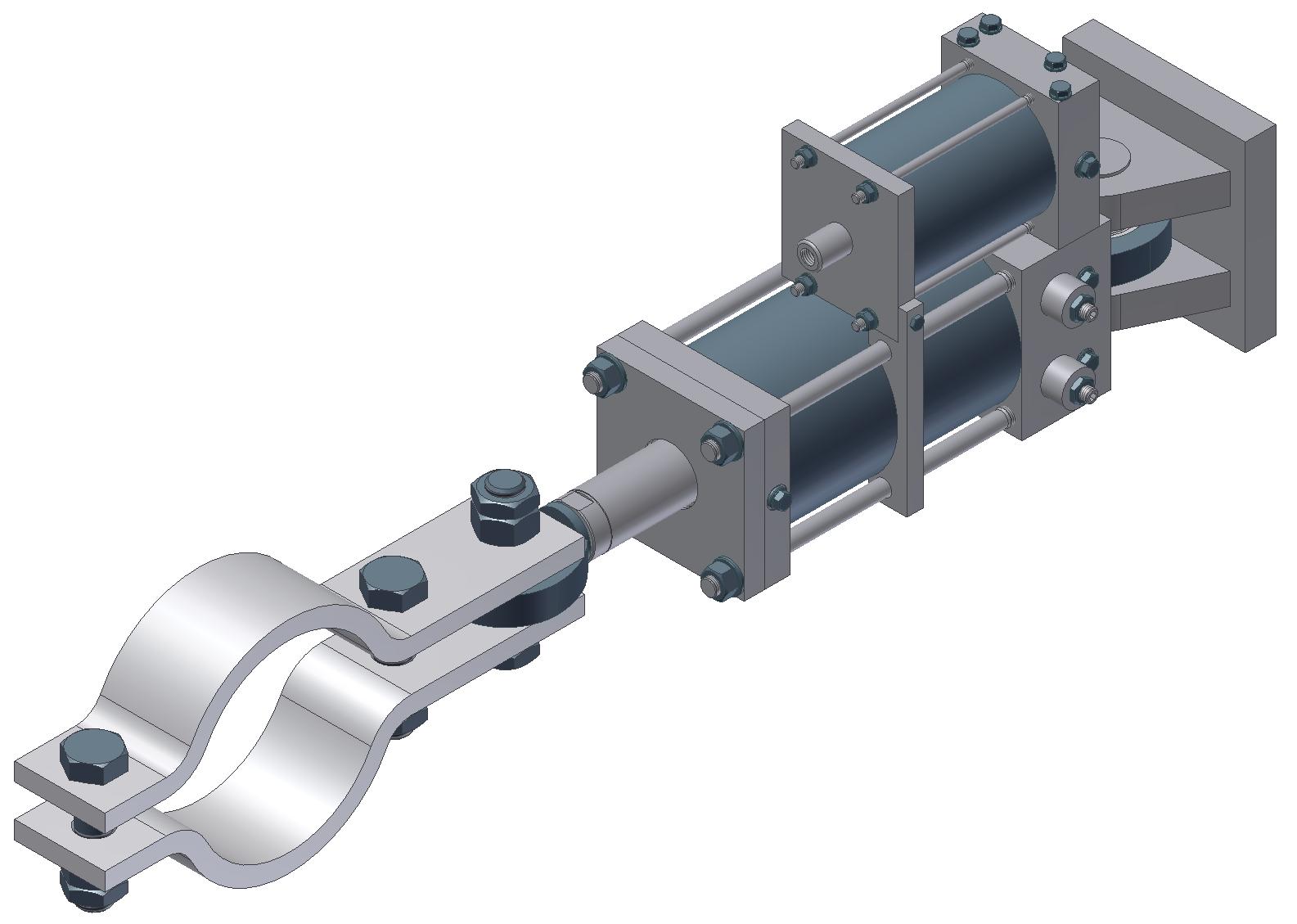

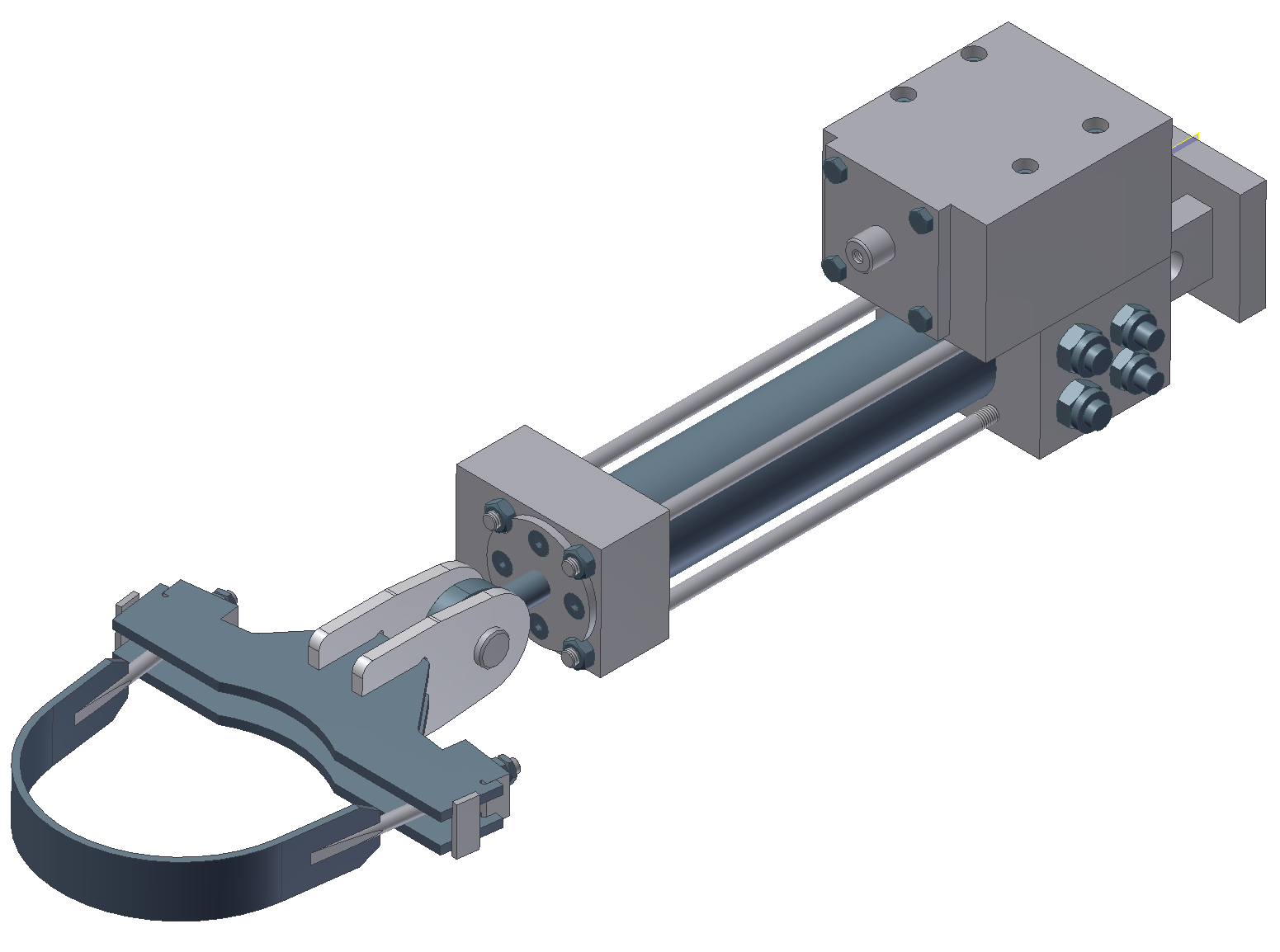

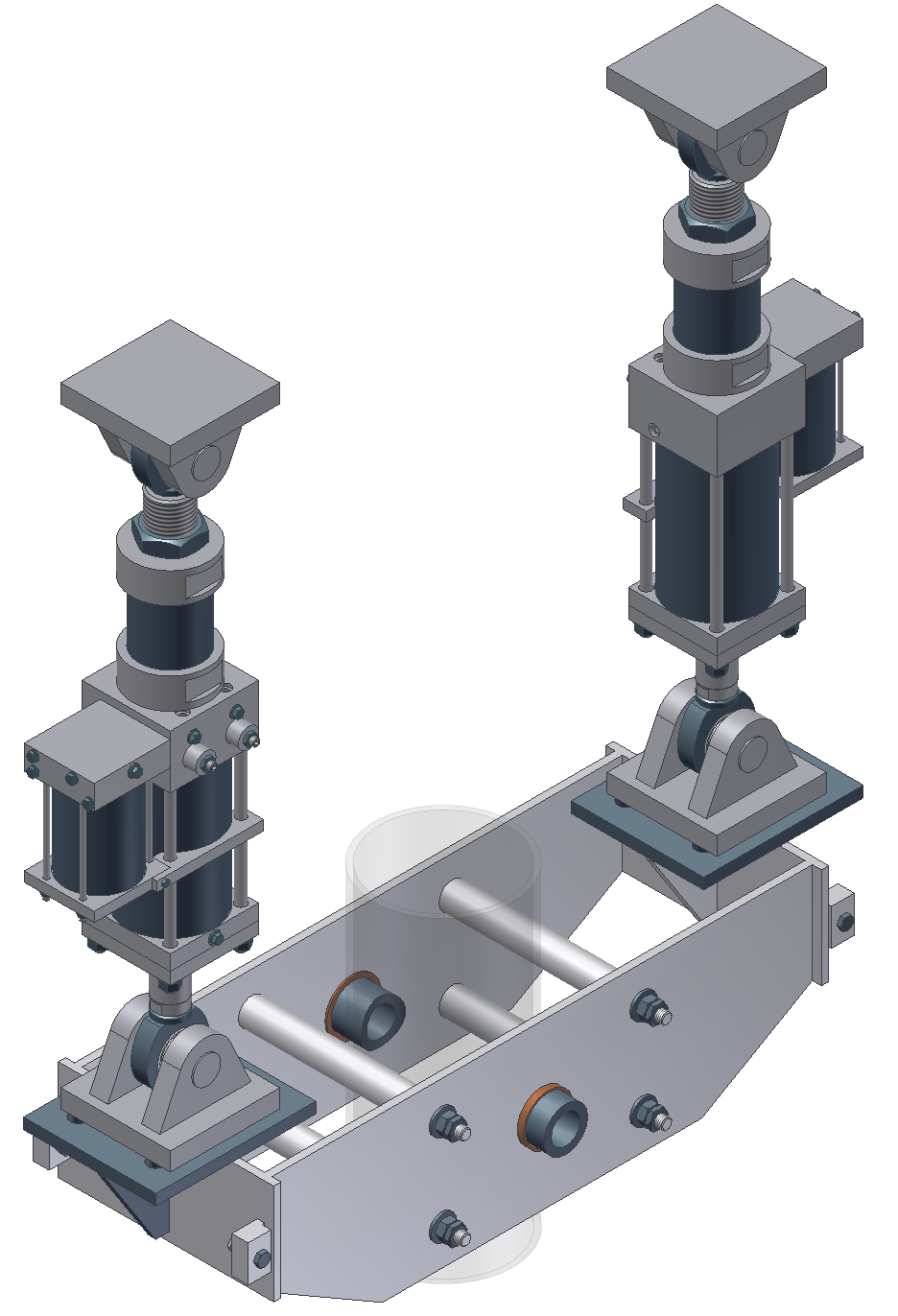

Connection and design options

For further information go to Downloads → catalogs → dynamicaly stressed pipe supports